Located in the Ormeau industrial park of Brisbane, Superkote Glass is a well established local company specialized in painted glass products for indoor applications. However, with the increasingly fierce market competition and customer demand for higher quality in recent years, Superkote’s executive, Mr. Kennedy decided to acquire a new high-end tempering equipment to replace the old existing ones.

A prudent selection with a tough condition

Being in the glass processing industry for many years, Mr. Kennedy has always had stringent requirements on the quality of the glass products, so to the new glass tempering furnace it planned to acquire. In order to locate an ideal glass tempering furnace, Mr. Kennedy spent a lot of time visiting glass tempering furnace manufacturers around the world.

At the time of signing the purchase contract, Mr. Kennedy requested LandGlass to complete the installation, commissioning, acceptance and start the operation in 18 days as the company just received a large order that would be crucial to the development of the company. They expected to move the company to the next level through this order.

A difficult task -to be completed within 18 days

It is indeed a tremendous challenge to complete the installation, commissioning, and acceptance of the glass tempering machine within 18 days. It requires the installation team to work around the clock as well as efficient collaboration and cooperation among various jobs. However, LandGlass is well experienced in handling this type of urgent situation with established solutions.

Prepare the planning drawings for installation in advance; confirm the equipment installation and commissioning plan; communicate with customers on a daily basis regarding the job progress; work around the clock to expedite the installation; have the process commissioning engineers at the installation place in advance; communicate with the customer in advance for a test run and arrange operating training when installation approaching the end - all work was carried out in a tense and orderly fashion under the supervision of LandGlass personnel.

A tremendous challenge, 4.8-meter-longsingle pane glass

On the morning of the 18th day, six large trucks were lined up outside the plant workshop of the Superkote Glass, waiting to transport the first batch of glass products produced by LandGlass glass tempering machine.

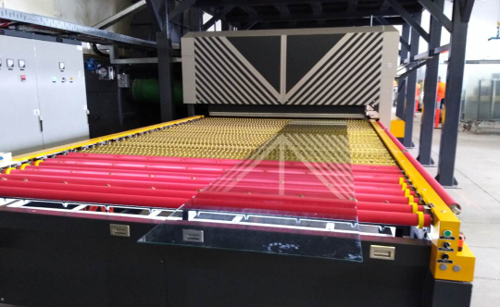

LandGlass successfully completed the installation, commissioning, and trial production in 18 days. Batches of glass products have been manufactured and shipped nationwide in Australia. Right at this moment, Superkote Glass received another urgent order for a batch of high-quality tempered glass with single-pane length up to 4.8 meters. Both the order and this customer are vital to the future development of Superkote Glass. Mr. Kennedy, the Superkote’s executive, was aware that it was a tough request, and as a professional, he also understood that it was a big challenge to the performance of LandGlass’ glass tempering furnace and as well to the competence of LandGlass’ engineers. While there was no better way, Mr. Kennedy brought the request to the LandGlass’ engineers at site and hoped to fulfill this order with their assistance, using the LandGlass A2442 glass tempering furnace to produce these 4.8 meters long single pane tempered glass pieces.

After a few rounds of equipment check, parameter adjustment, and testing, the 4.8 meters long glass panes finally rolled off the production line neatly. The Superkote Glass staff were all excited to see this. Mr. Kennedy shook hands with LandGlass’ process engineers to express his appreciation.

On the second day of the smooth operation, Superkote Glass printed posters for this event and informed all of their new and existing customers. On the poster, it reads, “With the assistance of LandGlass, the installation process that normally would have taken 5-6 weeks, has been completed in 18 days. Superkote Glass has returned to full operation. Supported by this great glass tempering machine, we are confident that we now can offer glass products of ever-higher quality to our customers. You are more than welcome to contact us for more information.”

Over the years, LandGlass has been committed to providing customers with custom-made high-end glass tempering equipment through continuous technological innovation. Thanks to its technical advantages and service strength, LandGlass was, is, and will be standing up to challenges and difficulties of any kind with full confidence as always.